Product Features:

1, high-pressure spray: to achieve attached to the cleaning agent on the top of the cleaning completely washed out.

2. Cleaning output: the hanging type can adjust the cleaning speed to reach the required output according to the requirement of the user’s cleaning quantity.

3, cleaning effect: according to the user cleaning quality requirements can be increased or decreased ultrasonic cleaning machine can also adjust the cleaning time. In order to meet the cleaning quality requirements.

4, blowing: because the position of the connecting rod is fixed, the blowing air outlet can be well placed. It can remove water from the oil hole.

5.Easy to operate: easy to operate. The hanging chain type operator only needs to be responsible for placing and unloading the cleaning parts, reducing the operator.

6, easy to clean: can clean various types of connecting rod, because the hanging transport is hanger transport, connecting rod hanger can be placed various connecting rod.

7. Easy to maintain: hanging chain. Transport equipment is circular, simple and practical, easy to maintain. This product support non-standard custom, can provide design drawings and cleaning program, metal tableware with hanging chain type multi-slot ultrasonic cleaning machine, non-standard custom ultrasonic cleaning machine

This product support non-standard custom, can provide design drawings and cleaning program

The hanging chain type multi-slot ultrasonic cleaning machine for the blue whale hardware tableware adopts the hanging conveyor chain and the special hanging implement, hangs the conveying work piece, sets up the multi-channel processes such as ultrasonic cleaning, rinsing, spraying, dehydration, drying, etc. , frequency converter stepless adjustment hanging chain running speed, to adapt to a variety of workpiece different needs of the cleaning rhythm, can be flexible layout according to the site cleaning procedures, smooth operation, high reliability, easy to operate, non-standard design according to different requirements of customers.

Configuration description: suspension chain flywheel hub ultrasonic, spray cleaning drying equipment from the suspension conveyor chain, driving device, tensioning device, ultrasonic cleaning, spray cleaning, over the sink, water cut system, drying system, piping system, filtering system, automatic temperature control device, total electrical control, chassis and rack and other parts. Stainless steel water plates are installed between the troughs to prevent water from dripping onto the ground during the movement of the automobile hub/flywheel.

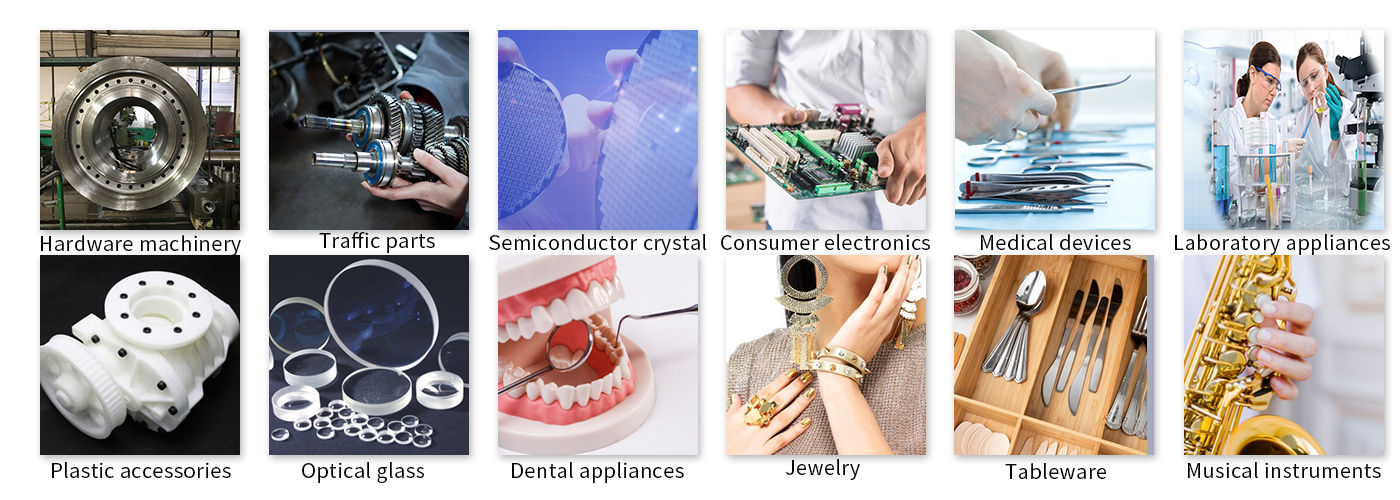

mainly used in machinery, electronics, jewelry, optics, medicine, coating, steam and vacuum coating pre-treatment and other related categories. For the surface shape of complex parts, such as the parts above the groove, slit, blind hole, deep hole cleaning has an efficient and rapid cleaning role. At the same time, the utility model can clean the oil, rust and oxide on the surface of the parts, and realize one-stop processing of cleaning, rinsing and stirring.

1、Determine the model

You can choose model through consultation. You can also understand the specifications and parameters and choose the model through the website. Our company can customize according to customer requirements. Welcome to the factory for inspection.

2、Inquiry

You can use telephone, online chat, messages, e-mail and other ways to get price and delivery term from sales manager.

3、Sign the contract

With product details and payment methods.

4、Payment

Payment will be made in accordance with the terms of the contract. Timely delivery will be arranged after payment.

5、Acceptance

When you receoved the machine, please check whether the outer packaging and goods are damaged. Also check the product model and quantity, as well as accessories. If the above happens, please take photos and contact with the sales staff.

6、After-sales service

1. Provide door-to-door installation and commissioning, technical personnel free guidance training;

2. After receiving feedback, we will give you response within 12 hours. We will come back to you with the solution within 36 hours;

3. We promise warranty for 18 months and provide to life-long maintenance. So you don’t need to worry about the after sales.