Product Features:

1, the use of city-state motors, accurate positioning, flexible arm handling;

2, fully closed management, to ensure that the cleaning environment clean;

3, Mitsubishi Programmable PLC automatic control, Taiwan Weilun man-machine interface;

4, to adapt to a variety of product cleaning, set up throttling wash;

5, water-based environmental ultrasonic cleaning, DI water washing, slow-pull dehydration tunnel-style hot air drying combined process;

6, support non-standard customization; Complete anti-dementia protection function safe and reliable, this product support non-standard custom, can provide design drawings and cleaning program.

This product support non-standard custom, can provide design drawings and cleaning program

Blue whale optical glass ultrasonic cleaning machine is a set of optical glass cleaning ultrasonic device, the user will install the workpiece fixture into the basket, hand-held into the tank for ultrasonic cleaning, when the preset cleaning time arrives, it is sent to each subsequent cleaning process tank in turn, and the processes of ultrasonic rough cleaning, ultrasonic fine cleaning, ultrasonic rinsing and slow drying of the workpiece are completed in turn, in order to complete a cleaning process, while the operator continues to place the basket from the tank, the fifth tank to take out the finished cleaning and drying work pieces, to deal with the cleaning operations in the cleaning area, the user can freely set the cleaning time, generally 3 ~ 6 minutes for a clean beat

The structure of optical glass ultrasonic cleaning machine consists of multi-channel ultrasonic cleaning tank, ultrasonic rinsing tank, slow pull drying tank, filtering circulation system, up and down shaking mechanism of workpiece, electrical control system and pure water supply system.

Optical glass ultrasonic cleaning machine construction:

1. The door of washing machine adopts door support structure, which can be installed freely, and is convenient for repair and maintenance.

2. The cleaning tank is provided with a unilateral overflow structure for optical glass cleaning, and a relevant storage tank and

3. The ultrasonic vibration plate adopts the structure of Taiwan machine and is connected with the groove body by screws and Teflon sealing material around the single vibration plate.

4. The control box is located on the upper vertical face of the left side of the washing machine, and the cleaning agent treatment configuration such as liquid storage tank and filtering circulation system is distributed on the back of the machine for easy daily maintenance. Protective device: equipped with emergency device: it is arranged in the spot and convenient to be pressed (in front of the washing tank body) , the utility model can enable the operator to disconnect the power of the whole cleaning system and stop all work and activities in real time in an emergency.

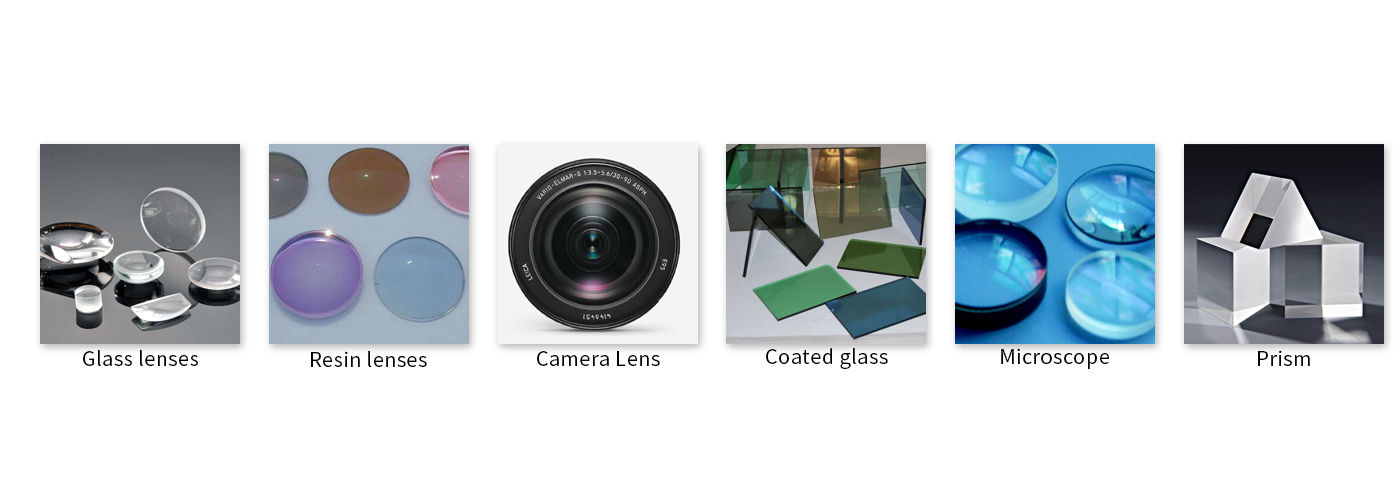

Blue whale optical glass ultrasonic cleaning machine, mainly used in: glass lens, resin lens, microscope, telescope, camera lens, coated glass, PRISM, lens and other optical products before and after coating and before assembly process cleaning; In the photoelectric industry mainly used in ITO conductive glass, LCD substrate cleaning, liquid crystal after packaging residual liquid crystal cleaning. Cleaning workpiece: projector, rear projection TV, digital cameras, automotive rearview mirrors and other optical glass.

1、Determine the model

You can choose model through consultation. You can also understand the specifications and parameters and choose the model through the website. Our company can customize according to customer requirements. Welcome to the factory for inspection.

2、Inquiry

You can use telephone, online chat, messages, e-mail and other ways to get price and delivery term from sales manager.

3、Sign the contract

With product details and payment methods.

4、Payment

Payment will be made in accordance with the terms of the contract. Timely delivery will be arranged after payment.

5、Acceptance

When you receoved the machine, please check whether the outer packaging and goods are damaged. Also check the product model and quantity, as well as accessories. If the above happens, please take photos and contact with the sales staff.

6、After-sales service

1. Provide door-to-door installation and commissioning, technical personnel free guidance training;

2. After receiving feedback, we will give you response within 12 hours. We will come back to you with the solution within 36 hours;

3. We promise warranty for 18 months and provide to life-long maintenance. So you don’t need to worry about the after sales.