Product Features:

1. continuous through-type cleaning machine, transmission speed variable frequency adjustable, high degree of automation, with high cleaning efficiency, easy operation and maintenance;

2. The cleaning pressure can be 0.3-1.5 mpa according to the different requirements of the workpiece.

3. cleaning cavity inside the nozzle according to demand can be up and down, right and left, side, fixed-point layout, to ensure that the cleaning total no dead angle;

4. the equipment technology choice is rich: ultrasonic cleaning, ultrasonic rinsing, spray cleaning, Compressed air cutting water, hot air drying, etc.

5. the equipment can be equipped with a real-time circulating filtration system, the utility model has the advantages of high liquid utilization efficiency, wide application range of equipment and low labor intensity;

This product support non-standard custom, can provide design drawings and cleaning program

Blue whale through ultrasonic cleaning machine, adopt through ultrasonic cleaning technology, using frequency 28 khz/40 khz/68 khz/80 khz/120 khz other ultrasonic frequency cleaning. The cleaning system is generally composed of spray system, nozzle rotating device, phosphating system, automatic temperature control and heating system, air cutting and water blowing system, etc.

For some specific cleaning objects, there are also hot air drying, special cleaning rack (basket) and cleaning fluid filtration circulation system. The main features of the through-type ultrasonic cleaning machine,first, it can avoid the surface damage of high-finish objects;second, it can remove the sub-micron size particles attached to the surface; third, it can be immersed in liquid, the side facing the transducer can be cleaned, so it is necessary to clean both sides.

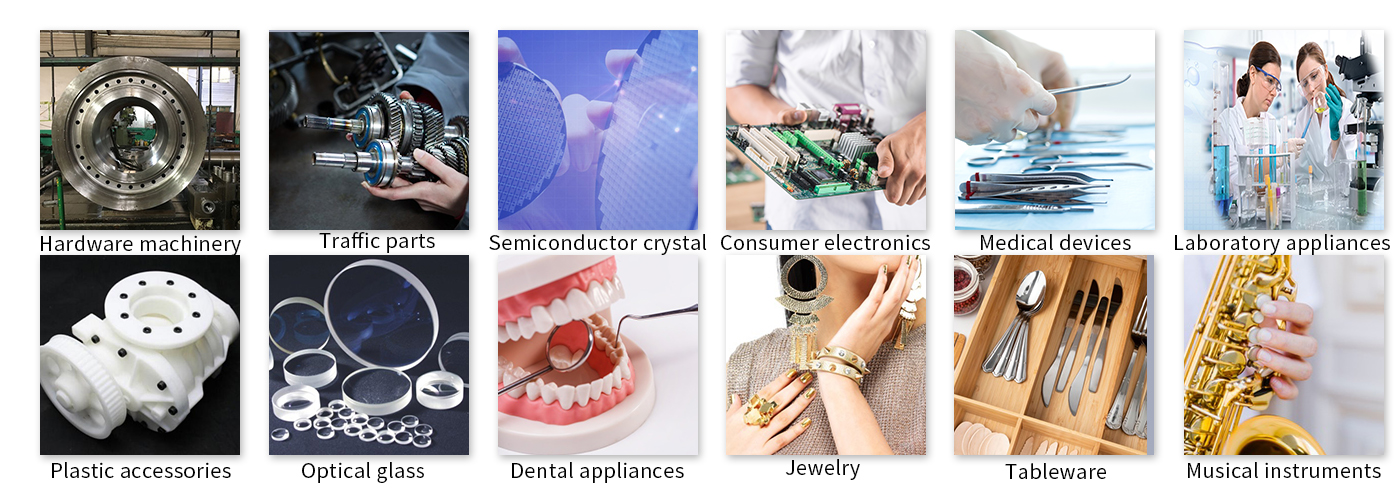

Blue Whale Through Type Ultrasonic Cleaning Machine, mainly used in machinery, electronics, jewelry, optics, medicine, painting, steam and vacuum coating pre-treatment and other related categories.

For the surface shape of complex parts, such as the parts above the groove, slit, blind hole, deep hole cleaning has an efficient and rapid cleaning role. At the same time, the utility model can clean the oil, rust and oxide on the surface of the parts, and realize one-stop processing of cleaning, spraying and drying.

1、Determine the model

You can choose model through consultation. You can also understand the specifications and parameters and choose the model through the website. Our company can customize according to customer requirements. Welcome to the factory for inspection.

2、Inquiry

You can use telephone, online chat, messages, e-mail and other ways to get price and delivery term from sales manager.

3、Sign the contract

With product details and payment methods.

4、Payment

Payment will be made in accordance with the terms of the contract. Timely delivery will be arranged after payment.

5、Acceptance

When you receoved the machine, please check whether the outer packaging and goods are damaged. Also check the product model and quantity, as well as accessories. If the above happens, please take photos and contact with the sales staff.

6、After-sales service

1. Provide door-to-door installation and commissioning, technical personnel free guidance training;

2. After receiving feedback, we will give you response within 12 hours. We will come back to you with the solution within 36 hours;

3. We promise warranty for 18 months and provide to life-long maintenance. So you don’t need to worry about the after sales.