-

Surface Treatment Processes Following Ultrasonic Cleaning

Surface Treatment Processes Following Ultrasonic Cleaning

After cleaning with anultrasonic cleaningdevice, the surface of the cleaned object may require additional processing to achieve the desired finish or functionality. Thesurface treatment processcan vary depending on the material and application of the obje

-

How to Prevent Rust After Ultrasonic Cleaning: 5 Scientifically Proven Protection Methods

How to Prevent Rust After Ultrasonic Cleaning: 5 Scientifically Proven Protection Methods

Proper rust prevention after ultrasonic cleaning is crucial for metal parts longevity. This guide covers industrial-grade passivation techniques, eco-friendly sealants, and cutting-edge nano-coatings to create durable anti-corrosion barriers while maintai

-

What Should Not Be Cleaned with an Ultrasonic Cleaner: Key Considerations and Restrictions

What Should Not Be Cleaned with an Ultrasonic Cleaner: Key Considerations and Restrictions

Ultrasonic cleaning is a powerful and efficient cleaning technique that uses high-frequency sound waves (typically 20-40 kHz) to create microscopic bubbles in a cleaning liquid. These bubbles form and collapse rapidly, a process known as cavitation, which

-

Ultrasonic Cleaners: The Pioneering Technology for Metal Cleaning

Ultrasonic Cleaners: The Pioneering Technology for Metal Cleaning

1. Introduction to Ultrasonic Cleaning Technology Ultrasonic cleaning has become one of the most effective and efficient methods for cleaning metal parts across various industries. This technology utilizes high-frequency sound waves (usually between 20

-

Determining Optimal Cleaning Time for Ultrasonic Cleaning of Aluminum Parts

Determining Optimal Cleaning Time for Ultrasonic Cleaning of Aluminum Parts

Ultrasonic cleaning machines are widely used in various industries for cleaning metal parts, including aluminum components. Aluminum parts often accumulate contaminants such as oils, greases, metal fines, and oxides during manufacturing processes, which c

-

Requirements for ultrasonic hardware cleaning machines. Features of hardware ultrasonic cleaning machine

Requirements for ultrasonic hardware cleaning machines. Features of hardware ultrasonic cleaning machine

The hardware usually refers to metal materials to manufacture various specifications and various shapes of metal objects, hardware is widely used in industry: trains, automobiles, aircraft, mechanical equipment, etc. Such objects are heavy and complex in

-

Application of full-automatic ultrasonic cleaning machine in phosphating treatment

Application of full-automatic ultrasonic cleaning machine in phosphating treatment

Working principle of ultrasonic cleaning machine: it is a high-frequency oscillation signal sent by the ultrasonic generator. It is transformed into high-frequency mechanical oscillation by the transducer and transmitted to a medium-cleaning solvent. The

-

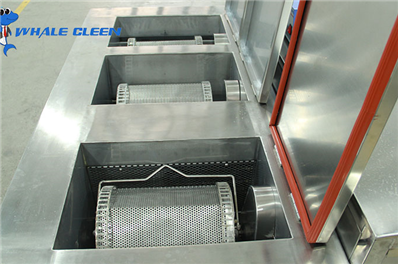

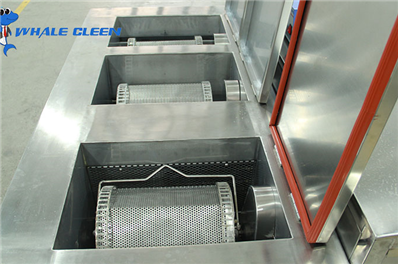

Ultrasonic cleaning machine for parts

Ultrasonic cleaning machine for parts

Part ultrasonic cleaning machine is an ultrasonic cleaning device designed for mechanical parts, hardware, or the like. Traditional cleaning parts generally adopted a method of using metal brushes, scrapers, and other tools to remove dirt on the surface o

Surface Treatment Processes Following Ultrasonic Cleaning

Surface Treatment Processes Following Ultrasonic Cleaning

How to Prevent Rust After Ultrasonic Cleaning: 5 Scientifically Proven Protection Methods

How to Prevent Rust After Ultrasonic Cleaning: 5 Scientifically Proven Protection Methods

What Should Not Be Cleaned with an Ultrasonic Cleaner: Key Considerations and Restrictions

What Should Not Be Cleaned with an Ultrasonic Cleaner: Key Considerations and Restrictions

Ultrasonic Cleaners: The Pioneering Technology for Metal Cleaning

Ultrasonic Cleaners: The Pioneering Technology for Metal Cleaning

Determining Optimal Cleaning Time for Ultrasonic Cleaning of Aluminum Parts

Determining Optimal Cleaning Time for Ultrasonic Cleaning of Aluminum Parts

Requirements for ultrasonic hardware cleaning machines. Features of hardware ultrasonic cleaning machine

Requirements for ultrasonic hardware cleaning machines. Features of hardware ultrasonic cleaning machine

Application of full-automatic ultrasonic cleaning machine in phosphating treatment

Application of full-automatic ultrasonic cleaning machine in phosphating treatment

Ultrasonic cleaning machine for parts

Ultrasonic cleaning machine for parts