-

Enhancing Electronic Device Performance: Ultrasonic Cleaning for Efficient Heat Sink Maintenance

Enhancing Electronic Device Performance: Ultrasonic Cleaning for Efficient Heat Sink Maintenance

Electronic heat sinks play a crucial role in modern electronic devices by dissipating heat efficiently to prevent overheating and ensure optimal performance. However, over time, the metal surfaces of electronic heat sinks can accumulate dust, dirt, and ot

-

Ultrasonic Cleaning for Metal Printing Machine Components: Ensuring Print Quality and Equipment Reliability

Ultrasonic Cleaning for Metal Printing Machine Components: Ensuring Print Quality and Equipment Reliability

Cleaning metal printing machine components is an essential step to ensure printing quality and equipment reliability. During the printing process, metal parts can accumulate ink residues, oil, and other impurities, which can negatively impact print qualit

-

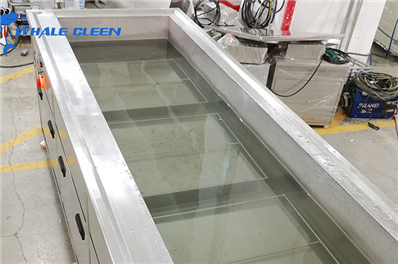

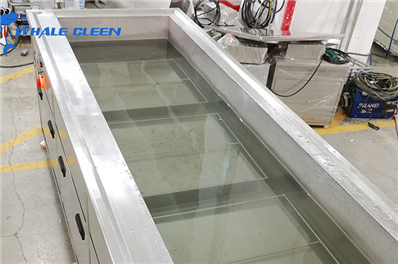

Why Can't Ultrasonic Cleaners Use Thin Steel Sheets? - An Engineering Analysis of Resonance Principles and Material Selection

Why Can't Ultrasonic Cleaners Use Thin Steel Sheets? - An Engineering Analysis of Resonance Principles and Material Selection

In the field of industrial manufacturing and equipment material selection, a fundamental principle is: "The right material for the right application." For ultrasonic cleaners, the choice of material for their core working component—the tank that

-

Why Did the Ultrasonic Cleaner Sound Suddenly Become Louder? Causes and Solutions

Why Did the Ultrasonic Cleaner Sound Suddenly Become Louder? Causes and Solutions

Ultrasonic cleaners are renowned for their efficiency in cleaning delicate items, from jewelry to medical instruments. However, when the device’s sound suddenly becomes louder than usual, it can be both alarming and indicative of an underlying issue. Unde

-

Why Has the Ultrasonic Cleaner's Sound Become Quieter? In-Depth Analysis and Restoration Guide

Why Has the Ultrasonic Cleaner's Sound Become Quieter? In-Depth Analysis and Restoration Guide

Anultrasonic cleanertypically emits a consistent humming sound during operation, which indicates normalultrasonic energytransmission. When this sound becomes noticeably quieter or disappears entirely, it often signals an underlying issue. Areduced soundno

-

How to Maintain and Clean an Ultrasonic Cleaner: The Ultimate Care Guide

How to Maintain and Clean an Ultrasonic Cleaner: The Ultimate Care Guide

Industry studies show that 60% of ultrasonic cleaner failures result from improper maintenance. This 800+ word guide provides professional-grade care protocols used by laboratory technicians and industrial operators to keep cleaners performing like new.

-

How to Calibrate an Ultrasonic Cleaner: A Step-by-Step Guide to Performance Verification

How to Calibrate an Ultrasonic Cleaner: A Step-by-Step Guide to Performance Verification

Article Content 1. The Importance of Calibrating Ultrasonic Cleaners (Keyword Density Optimization) Calibrating ultrasonic cleaners is essential for maintaining performance and reliability: Cleaning Efficiency: Uncalibrated machines c

-

How to Adjust Temperature on Ultrasonic Cleaners: A Complete Guide

How to Adjust Temperature on Ultrasonic Cleaners: A Complete Guide

Studies show that proper temperature control can improve cleaning efficiency by up to 40% and extend equipment life by 2-3 years. This guide will walk you through the steps to master temperature adjustment on your ultrasonic cleaner. 1. Understanding T

-

How to Disable Heating in Ultrasonic Cleaners: A Comprehensive Guide

How to Disable Heating in Ultrasonic Cleaners: A Comprehensive Guide

I. Reasons to Disable Heating 1. Application Scenarios Temperature-sensitive materials: Plastics (deformation risk above 50°C) Biological samples (prot

-

Why Don't Ultrasonic Cleaners Use Aluminum? Scientific Analysis and Practical Insights

Why Don't Ultrasonic Cleaners Use Aluminum? Scientific Analysis and Practical Insights

Ultrasonic cleaners are widely used in industries, laboratories, and households for their ability to remove contaminants from intricate surfaces. However, one notable observation is that these devices rarely use aluminum in their critical components, such

-

What is a Dual-Frequency Ultrasonic Cleaner? Comprehensive Analysis and Applications

What is a Dual-Frequency Ultrasonic Cleaner? Comprehensive Analysis and Applications

Introduction Ultrasonic cleaning is a widely recognized technology for achieving thorough cleaning in various industries, from healthcare to manufacturing. Traditional ultrasonic cleaners typically operate at a single frequency, which may limit their e

-

Understanding Advanced Ultrasonic Cleaning Machines: Features, Applications, and Advantages

Understanding Advanced Ultrasonic Cleaning Machines: Features, Applications, and Advantages

Introduction An advanced ultrasonic cleaning machine represents the pinnacle of modern cleaning technology, designed for applications demanding exceptional precision, efficiency, and reliability. Unlike standard ultrasonic cleaners, advanced models int

Enhancing Electronic Device Performance: Ultrasonic Cleaning for Efficient Heat Sink Maintenance

Enhancing Electronic Device Performance: Ultrasonic Cleaning for Efficient Heat Sink Maintenance

Ultrasonic Cleaning for Metal Printing Machine Components: Ensuring Print Quality and Equipment Reliability

Ultrasonic Cleaning for Metal Printing Machine Components: Ensuring Print Quality and Equipment Reliability

Why Can't Ultrasonic Cleaners Use Thin Steel Sheets? - An Engineering Analysis of Resonance Principles and Material Selection

Why Can't Ultrasonic Cleaners Use Thin Steel Sheets? - An Engineering Analysis of Resonance Principles and Material Selection

Why Did the Ultrasonic Cleaner Sound Suddenly Become Louder? Causes and Solutions

Why Did the Ultrasonic Cleaner Sound Suddenly Become Louder? Causes and Solutions

Why Has the Ultrasonic Cleaner's Sound Become Quieter? In-Depth Analysis and Restoration Guide

Why Has the Ultrasonic Cleaner's Sound Become Quieter? In-Depth Analysis and Restoration Guide

How to Maintain and Clean an Ultrasonic Cleaner: The Ultimate Care Guide

How to Maintain and Clean an Ultrasonic Cleaner: The Ultimate Care Guide

How to Calibrate an Ultrasonic Cleaner: A Step-by-Step Guide to Performance Verification

How to Calibrate an Ultrasonic Cleaner: A Step-by-Step Guide to Performance Verification

How to Adjust Temperature on Ultrasonic Cleaners: A Complete Guide

How to Adjust Temperature on Ultrasonic Cleaners: A Complete Guide

How to Disable Heating in Ultrasonic Cleaners: A Comprehensive Guide

How to Disable Heating in Ultrasonic Cleaners: A Comprehensive Guide

Why Don't Ultrasonic Cleaners Use Aluminum? Scientific Analysis and Practical Insights

Why Don't Ultrasonic Cleaners Use Aluminum? Scientific Analysis and Practical Insights

What is a Dual-Frequency Ultrasonic Cleaner? Comprehensive Analysis and Applications

What is a Dual-Frequency Ultrasonic Cleaner? Comprehensive Analysis and Applications

Understanding Advanced Ultrasonic Cleaning Machines: Features, Applications, and Advantages

Understanding Advanced Ultrasonic Cleaning Machines: Features, Applications, and Advantages