-

Optimal Frequency and Scope of Complimentary Maintenance for Ultrasonic Cleaning Machines

Optimal Frequency and Scope of Complimentary Maintenance for Ultrasonic Cleaning Machines

In the realm of industrial equipment maintenance, particularly concerning ultrasonic cleaning machines, the provision of complimentary maintenance services holds paramount importance. These services, offered typically by manufacturers or suppliers, aim to

-

Enhancing Plastic Product Quality with Ultrasonic Cleaning Technology

Enhancing Plastic Product Quality with Ultrasonic Cleaning Technology

In various industrial sectors, plastic products have become indispensable components. They serve critical roles in fields such as manufacturing, electronics, and healthcare. However, during production, transportation, and storage processes, plastic surfac

-

Ultrasonic Cleaning Machine: Removing Rust and Deposits from Metal Pipes

Ultrasonic Cleaning Machine: Removing Rust and Deposits from Metal Pipes

Cleaning metal pipes is a crucial procedure in various industrial applications. Metal pipes serve as essential components in systems transporting fluids, including liquids and gases. However, over time, the inner walls of these pipes tend to accumulate ru

-

Metal Tank Cleaning: Ultrasonic Technology for a Safe Storage Environment

Metal Tank Cleaning: Ultrasonic Technology for a Safe Storage Environment

Metal tanks are vital components in various industries for storing liquids, gases, and solids. Over time, the interior surfaces of these tanks accumulate deposits, residues, and contaminants, compromising their efficiency and potentially posing safety haz

-

Enhancing Combustion Efficiency and Safety: Ultrasonic Cleaning for Industrial Burners

Enhancing Combustion Efficiency and Safety: Ultrasonic Cleaning for Industrial Burners

Industrial burners play a crucial role in various manufacturing processes, providing heat and energy for operations such as heating, drying, and powering machinery. Over time, these burners can accumulate oil stains and dirt on their metal surfaces, leadi

-

The Apex of Clean Tech: Ultrasonic Cleaners and Their Unmatched Hygiene Safety

The Apex of Clean Tech: Ultrasonic Cleaners and Their Unmatched Hygiene Safety

In an era where hygiene and cleanliness have become paramount across industries, from healthcare to manufacturing, ensuring impeccable cleaning standards is crucial for both safety and performance. Ultrasonic cleaners have emerged as one of the most advan

-

How Ultrasonic Cleaners Enhance Industrial Equipment Cleaning Efficiency

How Ultrasonic Cleaners Enhance Industrial Equipment Cleaning Efficiency

In the modern industrial landscape, the efficiency and longevity of machinery are paramount to maintaining productivity and minimizing downtime. Contaminants such as oils, greases, carbon deposits, and other residues can accumulate on industrial equipment

-

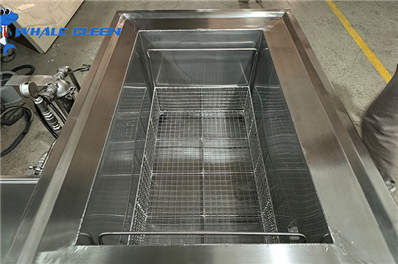

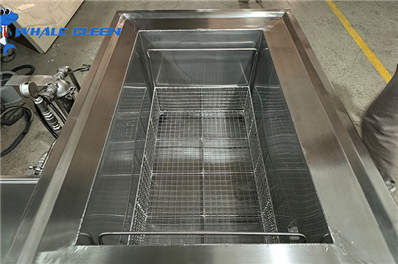

A New Approach to Industrial Equipment Cleaning: An In-Depth Analysis of Ultrasonic Cleaning Machines

A New Approach to Industrial Equipment Cleaning: An In-Depth Analysis of Ultrasonic Cleaning Machines

In the realm of industrial maintenance, ensuring that equipment is clean and functioning optimally is crucial for productivity, longevity, and safety. Traditional methods of cleaning often involve manual labor, chemical solvents, or abrasive techniques th

-

Why Does the Ultrasonic Cleaner Turn Things Black? Unveiling the Causes and Solutions

Why Does the Ultrasonic Cleaner Turn Things Black? Unveiling the Causes and Solutions

Discovering black particles floating in the water or a dark film on your items after ultrasonic cleaning can be alarming. Is your jewelry ruined? Is the machine faulty? In most cases, this "blackening" is a normal—even positive—indicator of the

-

Why Do Ultrasonic Cleaners Use 28kHz Frequency? The Science Behind the Power Setting

Why Do Ultrasonic Cleaners Use 28kHz Frequency? The Science Behind the Power Setting

When shopping for an ultrasonic cleaner, you'll quickly encounter a key specification: frequency. Among the most common options is28kHz. This number isn't arbitrary; it represents a deliberate engineering choice that makes this frequency a powerho

-

Why Can't Ultrasonic Cleaners Use Thin Steel Sheets? - An Engineering Analysis of Resonance Principles and Material Selection

Why Can't Ultrasonic Cleaners Use Thin Steel Sheets? - An Engineering Analysis of Resonance Principles and Material Selection

In the field of industrial manufacturing and equipment material selection, a fundamental principle is: "The right material for the right application." For ultrasonic cleaners, the choice of material for their core working component—the tank that

-

Why Do Ultrasonic Cleaners Have Multiple Cleaning Stages? The Science Behind the Process

Why Do Ultrasonic Cleaners Have Multiple Cleaning Stages? The Science Behind the Process

Ultrasonic cleaners are widely used in industries such as manufacturing, healthcare, jewelry, and automotive for their ability to clean intricate items with precision. However, many users wonder why these machines often involve multiple cleaning stages in

Optimal Frequency and Scope of Complimentary Maintenance for Ultrasonic Cleaning Machines

Optimal Frequency and Scope of Complimentary Maintenance for Ultrasonic Cleaning Machines

Enhancing Plastic Product Quality with Ultrasonic Cleaning Technology

Enhancing Plastic Product Quality with Ultrasonic Cleaning Technology

Ultrasonic Cleaning Machine: Removing Rust and Deposits from Metal Pipes

Ultrasonic Cleaning Machine: Removing Rust and Deposits from Metal Pipes

Metal Tank Cleaning: Ultrasonic Technology for a Safe Storage Environment

Metal Tank Cleaning: Ultrasonic Technology for a Safe Storage Environment

Enhancing Combustion Efficiency and Safety: Ultrasonic Cleaning for Industrial Burners

Enhancing Combustion Efficiency and Safety: Ultrasonic Cleaning for Industrial Burners

The Apex of Clean Tech: Ultrasonic Cleaners and Their Unmatched Hygiene Safety

The Apex of Clean Tech: Ultrasonic Cleaners and Their Unmatched Hygiene Safety

How Ultrasonic Cleaners Enhance Industrial Equipment Cleaning Efficiency

How Ultrasonic Cleaners Enhance Industrial Equipment Cleaning Efficiency

A New Approach to Industrial Equipment Cleaning: An In-Depth Analysis of Ultrasonic Cleaning Machines

A New Approach to Industrial Equipment Cleaning: An In-Depth Analysis of Ultrasonic Cleaning Machines

Why Does the Ultrasonic Cleaner Turn Things Black? Unveiling the Causes and Solutions

Why Does the Ultrasonic Cleaner Turn Things Black? Unveiling the Causes and Solutions

Why Do Ultrasonic Cleaners Use 28kHz Frequency? The Science Behind the Power Setting

Why Do Ultrasonic Cleaners Use 28kHz Frequency? The Science Behind the Power Setting

Why Can't Ultrasonic Cleaners Use Thin Steel Sheets? - An Engineering Analysis of Resonance Principles and Material Selection

Why Can't Ultrasonic Cleaners Use Thin Steel Sheets? - An Engineering Analysis of Resonance Principles and Material Selection

Why Do Ultrasonic Cleaners Have Multiple Cleaning Stages? The Science Behind the Process

Why Do Ultrasonic Cleaners Have Multiple Cleaning Stages? The Science Behind the Process