Knowledge | 2023-10-30

Effective Removal of Metal Contaminants from Electronic Waste using Ultrasonic Cleaning Technology

Return

Electronic waste (e-waste) poses a significant environmental challenge in today's society. E-waste encompasses discarded electronic devices and components, many of which contain various metal elements. These metals may be contaminated due to the presence of hazardous substances such as lead, mercury, and cadmium, which can infiltrate the metal components. Therefore, the effective cleaning of metal contaminants from e-waste is crucial. Ultrasonic cleaning machines represent a widely employed technology for this purpose. This article will provide a professional perspective on the topic.

Part 1: Metal Contamination in Electronic Waste

Metal contamination in e-waste primarily arises from two sources: first, metals used in electronic products may leach into the waste, and second, contamination may occur during the operational lifespan of the electronic device through wear and corrosion. The following are common metal contaminants found in e-waste:

-

Lead: Lead is extensively used in electronic connectors and circuit boards. In discarded electronic devices, lead may exist in various compound forms, posing severe risks to both human health and the environment.

-

Mercury: Mercury is often present in electronic components like fluorescent lamps, batteries, and switches. Mercury contamination can lead to significant issues in water bodies and ecosystems.

-

Cadmium: Cadmium is commonly used for plating metal parts, such as electronic connectors. It is a highly toxic heavy metal, posing threats to both human health and the environment.

-

Other Metals: E-waste also contains various other metal elements, including copper, aluminum, nickel, chromium, and more. While not as hazardous as lead, mercury, and cadmium, these metals can still have adverse environmental impacts at high concentrations.

Due to the presence of these metal contaminants, proper handling and cleaning of e-waste are crucial to mitigate potential harm to the environment and human health.

Part 2: Ultrasonic Cleaning Technology

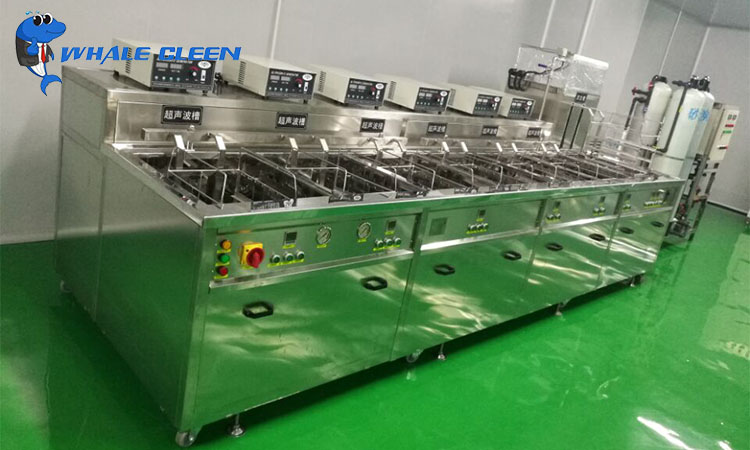

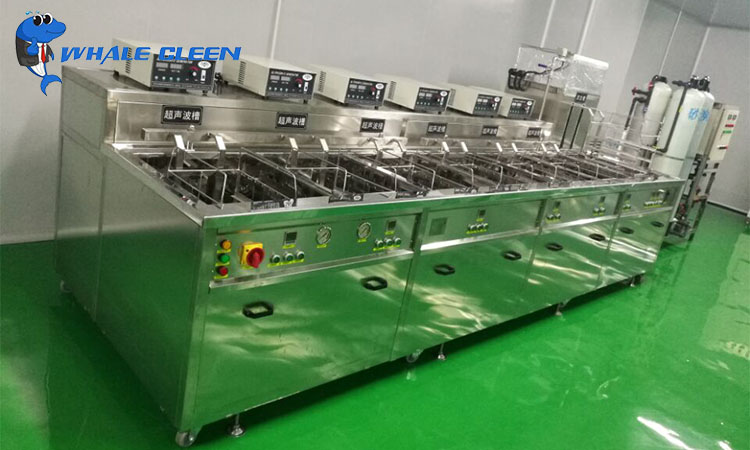

Ultrasonic cleaning technology is a physical method that generates high-frequency sound wave vibrations in a cleaning solution. This generates tiny bubbles, which, upon collapse, release powerful energy, effectively removing dirt and contaminants. An ultrasonic cleaning machine typically comprises an ultrasonic generator, a tank filled with cleaning solution, and appropriate cleaning agents. The working principle of an ultrasonic cleaning machine is as follows:

-

Ultrasonic Generator: The ultrasonic generator in the machine produces high-frequency sound waves, typically ranging from 20kHz to 40kHz. These waves propagate into the cleaning solution, leading to the formation and collapse of bubbles.

-

Bubble Formation and Collapse: The high-frequency vibrations generated by the sound waves form tiny bubbles in the liquid. These bubbles continuously form and collapse due to the action of the ultrasonic vibrations. When the bubbles collapse, they release energy, creating powerful micro-shock waves that can dislodge dirt and contaminants adhering to surfaces.

-

Cleaning Solution: The selection of the cleaning solution is a critical factor in ultrasonic cleaning. Different types of solutions are suitable for removing different types of dirt. The cleaning solution is typically a water-based liquid that may contain surfactants and other chemicals to enhance cleaning effectiveness.

Part 3: Applications of Ultrasonic Cleaning Machine in E-waste Treatment

The ultrasonic cleaning machine finds widespread application in the treatment of electronic waste, including:

-

Connector Cleaning: Electronic connectors are crucial components of electronic devices, often containing metal pins and connectors. These connectors may become contaminated, and the ultrasonic cleaning machine effectively removes dirt and oxides from their surfaces, ensuring proper functionality and reliability.

-

Circuit Board Cleaning: Metal components on circuit boards may become contaminated. The ultrasonic cleaning machine aids in removing dirt from their surfaces, ensuring the performance and reliability of the circuit board.

-

Metal Part Cleaning: E-waste may include various metal parts, such as heat sinks and metal casings. These metal parts may be affected by grease, dirt, and corrosion. The ultrasonic cleaning machine effectively removes these contaminants, restoring the performance of the metal parts.

-

Other Applications: The ultrasonic cleaning machine can also be used to clean other metal components in e-waste, such as sensors, wires, and more.

Conclusion:

Ultrasonic cleaning technology offers significant advantages in removing metal contaminants from e-waste. By utilizing the micro-bubbles and shock waves generated by sound wave vibrations, ultrasonic cleaning machines can effectively eliminate metal pollutants from electronic waste, ensuring safe and environmentally friendly waste disposal. However, in practical applications, the selection of appropriate cleaning agents and parameters is crucial to maximize cleaning effectiveness. Therefore, ultrasonic cleaning technology stands as an efficient and reliable method for addressing metal contamination in e-waste, with broad prospects in environmental protection and e-waste management.