.jpg)

1, drying trough: self-regulation, time and temperature, with drying to complete the alarm notice function; 2, inner liner material: using 304 stainless steel, thickened to 2mm, manual argon welding, solid and durable; 3, Time Adjustable: 1-99 minu

Operation Requirements, simple: 1, automatic operation, no long-term supervision staff. 2. Automation of cleaning and maintenance, avoiding perceived interference. Area, Small: 1, Pretreatment Pool Small area, do not need the middle pool.

Automatic hydrocarbon vacuum ultrasonic cleaning machine, is a use of liquid in the vacuum state of physical changes, to change some of the characteristics of hydrocarbon cleaning machine, can make up for the shortcomings of hydrocarbon solvents, so that the advantages of the hydrocarbon cleaning machine is maximized, ……

1. continuous through-type cleaning machine, transmission speed variable frequency adjustable, high degree of automation, with high cleaning efficiency, easy operation and maintenance; 2. The cleaning pressure can be 0.3-1.5 mpa according to the differ

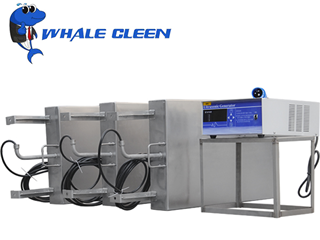

The blue whale battery shell mold uses the mechanical arm full automatic ultrasonic cleaner, mainly by: mechanical transmission system, ultrasonic system, heating system, drying system, water supply and drainage system and electrical control system composed of six parts, generally using PLC control, easy to operate, th……

1. Adopt imported adhesive and key bonding process to ensure the transducer works for a long time at, 120 °C water temperature and is durable; 2. Adopt unique digital ultrasonic generator, for other exciting circuit structure, MCU control, IGBT working