-

Enhancing Heat Exchanger Performance through Ultrasonic Cleaning

Enhancing Heat Exchanger Performance through Ultrasonic Cleaning

Cleaning metal heat exchangers is essential to maintain their efficient operation and extend their lifespan. Heat exchangers are widely used in various industrial and domestic equipment, such as air conditioners, cooling systems, heating systems, petroche

-

Optimizing Heating Efficiency in Ultrasonic Cleaning Machines: Professional Insights

Optimizing Heating Efficiency in Ultrasonic Cleaning Machines: Professional Insights

Ultrasonic cleaning machines are widely used in various industries for their effectiveness in removing contaminants from objects through the use of high-frequency sound waves. One crucial aspect of ultrasonic cleaning machines is their ability to maintain

-

Design Features of Ultrasonic Cleaning Equipment: Enhancing Efficiency and Safety

Design Features of Ultrasonic Cleaning Equipment: Enhancing Efficiency and Safety

Ultrasonic cleaning equipment is widely used in various industries for efficient and thorough cleaning. These devices are equipped with several design features that contribute to their effectiveness and versatility. In this article, we will delve into the

-

Why do people choose an ultrasonic cleaner tank to clean parts?

Why do people choose an ultrasonic cleaner tank to clean parts?

Here we tell you the difference between the original cleaning method and the current high-tech cleaning equipment. The soaking and cooking belong to the original cleaning method. Among them, immersion is to soak the parts to be cleaned in the clean

-

Why Do Ultrasonic Cleaners Use 28kHz Frequency? The Science Behind the Power Setting

Why Do Ultrasonic Cleaners Use 28kHz Frequency? The Science Behind the Power Setting

When shopping for an ultrasonic cleaner, you'll quickly encounter a key specification: frequency. Among the most common options is28kHz. This number isn't arbitrary; it represents a deliberate engineering choice that makes this frequency a powerho

-

Why Do Ultrasonic Cleaners Heat Up? The Science Behind Temperature Rise and Practical Solutions

Why Do Ultrasonic Cleaners Heat Up? The Science Behind Temperature Rise and Practical Solutions

Ultrasonic cleaners have become essential tools in various industries, from jewelry cleaning to industrial parts maintenance. Many users notice that during operation, the cleaning solution and the device itself gradually heat up. This phenomenon often rai

-

How to Adjust Temperature on Ultrasonic Cleaners: A Complete Guide

How to Adjust Temperature on Ultrasonic Cleaners: A Complete Guide

Studies show that proper temperature control can improve cleaning efficiency by up to 40% and extend equipment life by 2-3 years. This guide will walk you through the steps to master temperature adjustment on your ultrasonic cleaner. 1. Understanding T

-

How to Disable Heating in Ultrasonic Cleaners: A Comprehensive Guide

How to Disable Heating in Ultrasonic Cleaners: A Comprehensive Guide

I. Reasons to Disable Heating 1. Application Scenarios Temperature-sensitive materials: Plastics (deformation risk above 50°C) Biological samples (prot

-

How to Measure an Ultrasonic Cleaner? Comprehensive Guide and Practical Tips

How to Measure an Ultrasonic Cleaner? Comprehensive Guide and Practical Tips

1. The Importance of Measuring Ultrasonic Cleaners The performance of an ultrasonic cleaner directly impacts cleaning efficiency and equipment lifespan. Regular measurement helps avoid issues such as: Reduced Cleaning Efficiency: Aging o

-

What is a Carbon Hydrogen Ultrasonic Cleaning Machine?

What is a Carbon Hydrogen Ultrasonic Cleaning Machine?

A Carbon Hydrogen Ultrasonic Cleaning Machine is a specialized industrial cleaning device that combines the power of ultrasonic technology with the use of carbon-hydrogen (hydrocarbon) solvents to remove contaminants from various surfaces. This type of ma

-

What Type of Water Pump is Used in Ultrasonic Cleaning Machines? A Detailed Analysis

What Type of Water Pump is Used in Ultrasonic Cleaning Machines? A Detailed Analysis

Ultrasonic cleaning technology is widely used in various industries due to its efficient cleaning performance, particularly in precision cleaning. This technology relies on high-frequency sound waves to create cavitation bubbles in a cleaning liquid, whic

-

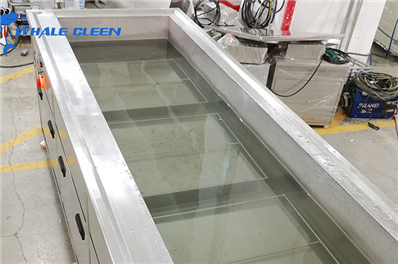

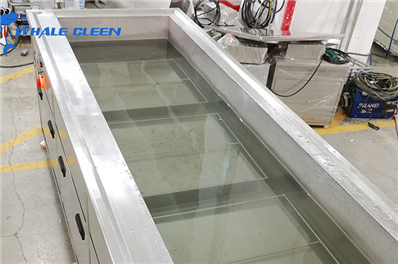

What is a Single-Tank Ultrasonic Cleaning Machine? A Comprehensive Overview

What is a Single-Tank Ultrasonic Cleaning Machine? A Comprehensive Overview

Ultrasonic cleaning technology has become an essential process in many industries for efficiently removing contaminants from surfaces, especially where precision and delicate handling are crucial. Among the various types of ultrasonic cleaners, the single

Enhancing Heat Exchanger Performance through Ultrasonic Cleaning

Enhancing Heat Exchanger Performance through Ultrasonic Cleaning

Optimizing Heating Efficiency in Ultrasonic Cleaning Machines: Professional Insights

Optimizing Heating Efficiency in Ultrasonic Cleaning Machines: Professional Insights

Design Features of Ultrasonic Cleaning Equipment: Enhancing Efficiency and Safety

Design Features of Ultrasonic Cleaning Equipment: Enhancing Efficiency and Safety

Why do people choose an ultrasonic cleaner tank to clean parts?

Why do people choose an ultrasonic cleaner tank to clean parts?

Why Do Ultrasonic Cleaners Use 28kHz Frequency? The Science Behind the Power Setting

Why Do Ultrasonic Cleaners Use 28kHz Frequency? The Science Behind the Power Setting

Why Do Ultrasonic Cleaners Heat Up? The Science Behind Temperature Rise and Practical Solutions

Why Do Ultrasonic Cleaners Heat Up? The Science Behind Temperature Rise and Practical Solutions

How to Adjust Temperature on Ultrasonic Cleaners: A Complete Guide

How to Adjust Temperature on Ultrasonic Cleaners: A Complete Guide

How to Disable Heating in Ultrasonic Cleaners: A Comprehensive Guide

How to Disable Heating in Ultrasonic Cleaners: A Comprehensive Guide

How to Measure an Ultrasonic Cleaner? Comprehensive Guide and Practical Tips

How to Measure an Ultrasonic Cleaner? Comprehensive Guide and Practical Tips

What is a Carbon Hydrogen Ultrasonic Cleaning Machine?

What is a Carbon Hydrogen Ultrasonic Cleaning Machine?

What Type of Water Pump is Used in Ultrasonic Cleaning Machines? A Detailed Analysis

What Type of Water Pump is Used in Ultrasonic Cleaning Machines? A Detailed Analysis

What is a Single-Tank Ultrasonic Cleaning Machine? A Comprehensive Overview

What is a Single-Tank Ultrasonic Cleaning Machine? A Comprehensive Overview